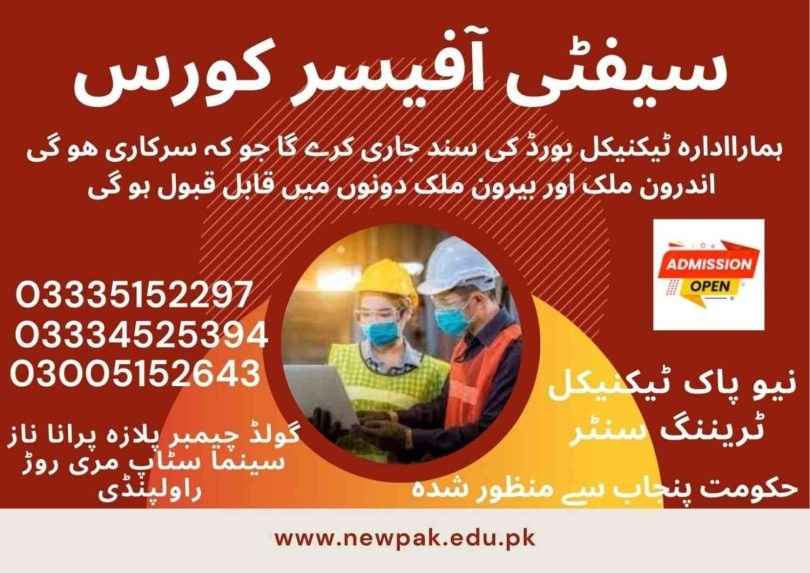

Safety Officer Course In Rawalpindi Islamabad

The Workplace Safety Training is designed to equip employees and aspiring site safety officers with the knowledge and skills to identify and mitigate workplace hazards, reduce the risk of accidents and injuries, and promote a safe working environment. This training also supports the role of a safety and health officer by covering key topics such as hazard identification and assessment, personal protective equipment, emergency preparedness, and accident investigation.

Course Overview

The 6-month Safety Officer Course in Islamabad covers foundational topics such as occupational health and safety principles, hazard identification, risk assessment, accident prevention, emergency preparedness, use of PPE, and safety communication techniques. The 1-year advanced version includes all basic modules and adds in-depth training on industrial hygiene, ergonomics, safety management systems, confined space safety, electrical and machinery safety, and chemical safety, along with practical training sessions. This safety course is ideal for professionals aiming to work as safety officers or advance to roles like the safety director, enabling them to manage workplace safety and implement comprehensive safety protocols.

Course Duration

06 | Months

- Introduction to Occupational Health & Safety (OH&S)

- Hazard Identification & Risk Assessment

- Accident Prevention & Investigation

- Emergency Preparedness & Fire Safety

- Personal Protective Equipment (PPE) & Work Permits

- Safety Communication & Safety Culture

01 | Year

- Introduction to Occupational Health & Safety (OH&S)

- Hazard Identification & Risk Assessment

- Accident Prevention & Investigation

- Emergency Preparedness & Fire Safety

- Personal Protective Equipment (PPE) & Work Permits

- Safety Communication & Safety Culture

- Industrial Hygiene

- Ergonomics & Workplace Design

- Safety Management Systems (SMS)

- Confined Space Safety

- Electrical & Machinery Safety

- Chemical Safety & Practical Training

Course Outline (6 Months)

Occupational Health & Safety (OH&S) Basics

Month 1

- Importance of workplace safety

- Overview of OH&S legislation and standards

- Roles and responsibilities of safety officers

- Introduction to workplace hazards

Hazard Identification and Risk Assessment

Month 2

- Common workplace hazards (slips, trips, falls, electrical, etc.)

- Hazard identification techniques

- Risk assessment process and tools

- Control measures and hierarchy of controls

Accident Prevention and Investigation

Month 3

- Causes and types of workplace accidents

- Preventive measures and control strategies

- Accident investigation procedures

- Root cause analysis

Emergency & Fire Safety

Month 4

- Emergency response planning

- Evacuation procedures and drills

- Types of fires and fire classifications

- Use of fire extinguishers and fire safety equipment

Personal Protective Equipment (PPE)

Month 5

- Types of PPE and their applications

- Proper use, maintenance, and limitations of PPE

- Work permit system: hot work, confined space, and electrical work permits

- Documentation and procedural control

Safety Communication & Safety Culture

Month 6

- Effective safety communication methods

- Promoting a positive safety culture in the workplace

- Employee participation and engagement in safety programs

- Safety meetings, toolbox talks, and training sessions

Course Outline (1-Year)

Months 1–6: Basic Safety Officer Course In Rawalpindi Islamabad

(Same course content as the 6-month program but with more detail, role-plays, software technologies, and hands-on practice.)

Workplace Hygiene & Safety

Month 7

- Recognition and evaluation of health hazards

- Physical, chemical, biological, and ergonomic hazards

- Monitoring methods and instrumentation

- Control strategies for workplace exposures

Ergonomics and Space Planning

Month 8

- Principles of ergonomics

- Designing workstations to reduce strain and injury

- Manual handling and lifting safety

- Ergonomic assessments and interventions

Safety Management system

Month 9

- Introduction to SMS and safety policies

- Planning, implementation, and evaluation

- Key performance indicators for safety

- Continuous improvement strategies

Confined Space Work Safety

Month 10

- Definition and types of confined spaces

- Hazards and risks associated with confined space entry

- Entry permits, gas testing, and ventilation requirements

- Roles and responsibilities of the entry team

Global Trends & Cultural Training

Month 11

- Hazards of electricity and electrical systems

- Lockout/tagout procedures

- Machine guarding principles

- Safe work practices for operating equipment

Internship + Final Project

Month 12

- Classification and handling of hazardous chemicals

- Safety Data Sheets (SDS) and labeling standards

- Chemical storage and spill response

Career Opportunities

- Occupational Health and Safety (OHS) Specialist

- Environmental Health and Safety (EHS) Specialist

- Safety Engineer

- Risk Manager

- Safety Trainer

- Industrial Hygienist

- Emergency

- Management Specialist

- Fire Safety Officer

- Ergonomics Specialist

Conclusion

The Safety Officer Course In Rawalpindi Islamabad equips participants to identify hazards, manage risks, and maintain safe work environments. This safety training prepares individuals for roles such as health and safety officer, or even site safety officer, contributing effectively to workplace safety under the guidance of the safety director.